Marthinusen & Coutts (M&C), a division of ACTOM (Pty) Ltd, successfully installed the stator winding for 2 GMD motors in Northern Zambia. The installation was completed in record time.

Both the SAG and Ball motors, 4 x 2 eight-quadrant joints, and coils were installed and connected to drive the mills. The SAG mill is among the largest in Africa, with a diameter of 15.2 metres, a length of 6.5 metres, and an installed power rating of 28MW. This mill is designed to grind 2,450 t/h or 20 million tonnes per annum.

These are considered to be the largest electric motors in Africa: the Ball mill is driven by a 22MW, 64-pole, 4,000-volt motor with 480 slots, and the SAG mill by an 28MW, 88-pole, 4,000-volt motor with 648 slots.

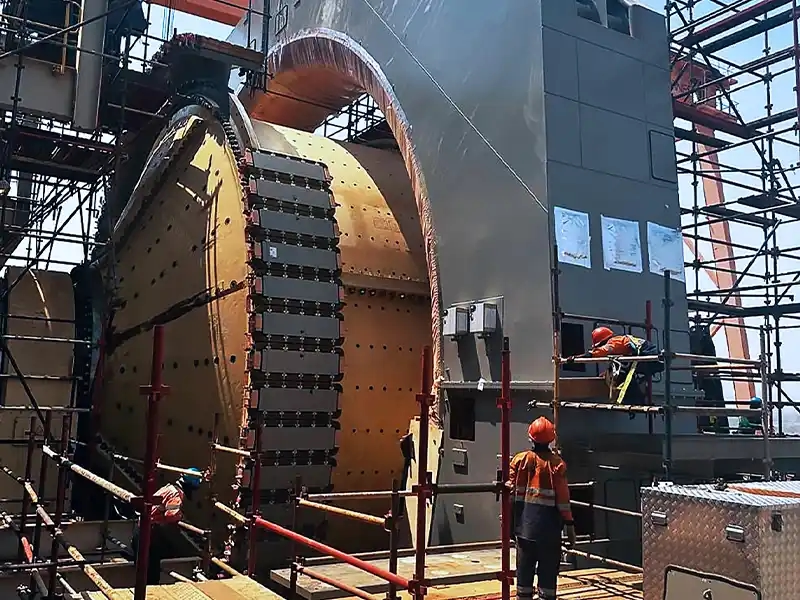

The motors are so large that they are transported in quartered sections and then assembled on site using some of the largest mobile cranes available. Each quadrant weighs about 65 tonnes, and the total motor dimensions are 20 by 3 metres, with a stator ID of 15.2 metres.

Each joint has seven large (uninsulated overhang) ‘flexible’ coils, which help manage the pitch, while the remaining coils are standard resin-rich diamond-type coils, each weighing 44kg.

Since the mill drives are exposed to weather, special precautions must be taken to protect the windings from all elements, preventing moisture and dirt from entering. Custom-designed equipment and tools are necessary for various tasks. Led by Richard Botton, M&C CEO, M&C assembled a team of 10 specialists to undertake various functions and tasks, ensuring the installation was carried out to the highest standard.

Throughout the process, M&C ensured quality control measures were implemented, carefully checking each stage of the repair work to ensure compliance with industry standards. M&C conducted a series of inspections and operational checks to ensure the mill was operating properly.

As part of their comprehensive testing protocol, the team monitored parameters including electrical currents, temperatures, and mechanical responses. The SAG and Ball mill motors were installed successfully within a record time of 31 and 28 days, respectively. M&C once again demonstrated its ability to deliver superior on-site engineering services to complete such a large project, ensuring the mill was commissioned and operational in the shortest possible time.